Product Details

| Product name | E-Glass Assembled Roving For Spray Up | ||

| MOQ | ≥1000KG | ||

| Application | mainly used for producing GRP ships,sanitary ware,storage tanks and Hobas pipes,etc | ||

| Feature | 1. Good cutting performance 2. Excellent molding performance 3. Easy bubble release 4. Penetration rate is moderate 5. Good dispersion performance 6. Compatible with various resins | ||

PERFORMANCE ATTRIBUTES

COMPATIBLE WITH VARIOUS RESINS

GOOD CUTTING PERFORMANCE

EXCELLENT MOLDING PERFORMANCE

GOOD DISPERSION PERFORMANCE

Specifications

| Item | Specification | Standard No. | |

| Linear density (tex) | 2400±120 | 3000±150 | ISO 1889 - 1997 |

| Loss on ignition ( % ) | 1.00±0.15 | 1.00±0.15 | ISO 1887 - 1995 |

| Moisture content ( % ) | ≤0.1 | ≤0.1 | ISO 3344 - 1997 |

| Stiffness (mm) | 135±15 | 135±15 | ISO 3375 - 1997 |

Technical Parameter

| product code | Fiber Type | Linear Density(tex) | Single filament diameter (μm) | Applicable resin | Combustible content (%) |

| ER-2400-618 | E-Glass | 2400 | 13 | UP, VE | 1.2-1.6 |

| ER-4800-618 | E-Glass | 4800 | 13 | UP, VE | 1.2-1.6 |

APPLICATION

It is a versatile general purpose spray-up roving used to manufacture boats, yacht, sanitary ware, swimming pool and automotive parts and also pipe by centrifugal casting process.Advantage

ZBREHON Fiberglass roving for spraying is formulated with silane-enhanced sizing, which has excellent chopping smoothness, good antistatic and dispersibility, fast soaking, no springback at small angle of the product, and high product strength. Moderate soaking, good molding performance, good mechanical properties of products, good use processability, can be used in manipulator spraying process. and there have these advantage: 1. Excellent static control 2. Excellent choppability and dispersion 3. Fast and complete wet-out ensures easy roll-out and rapid air release 4. Excellent strength of the composite products 5. Excellent hydrolysis-resistance of finished parts 6. High strength of end products and good resistance to boiling water

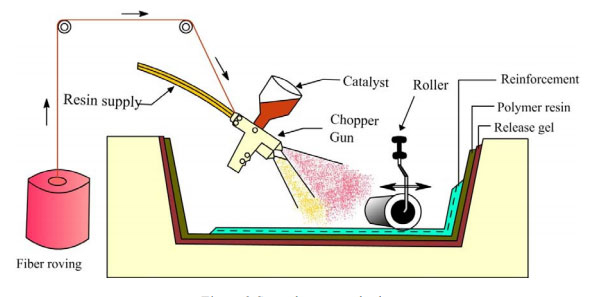

Spray lay-up Process

The spraying process can be said to be an extension of the manual laying process. In this technique, resin under pressure and reinforcement in the form of chopped fibers are sprayed with a spray gun. Typically, glass roving is used as reinforcement, which is passed through a spray gun and then chopped with a chipping gun. The base material and the reinforcing material can be sprayed simultaneously or sequentially. A release gel spray is applied to the surface of the mold to facilitate removal of the component from the mold. The roller is rolled over the sprayed material to remove air trapped in the coating. After the fibers and resin are sprayed to the desired thickness, the product is cured at room temperature or elevated temperature. After curing, the mold is opened and the developed composite part is removed for further processing. The curing time depends on the type of polymer used to process the composite. A schematic diagram of the spraying process is as follows:

The spraying process can be said to be an extension of the manual laying process. In this technique, resin under pressure and reinforcement in the form of chopped fibers are sprayed with a spray gun. Typically, glass roving is used as reinforcement, which is passed through a spray gun and then chopped with a chipping gun. The base material and the reinforcing material can be sprayed simultaneously or sequentially. A release gel spray is applied to the surface of the mold to facilitate removal of the component from the mold. The roller is rolled over the sprayed material to remove air trapped in the coating. After the fibers and resin are sprayed to the desired thickness, the product is cured at room temperature or elevated temperature. After curing, the mold is opened and the developed composite part is removed for further processing. The curing time depends on the type of polymer used to process the composite. A schematic diagram of the spraying process is as follows: