Product Details

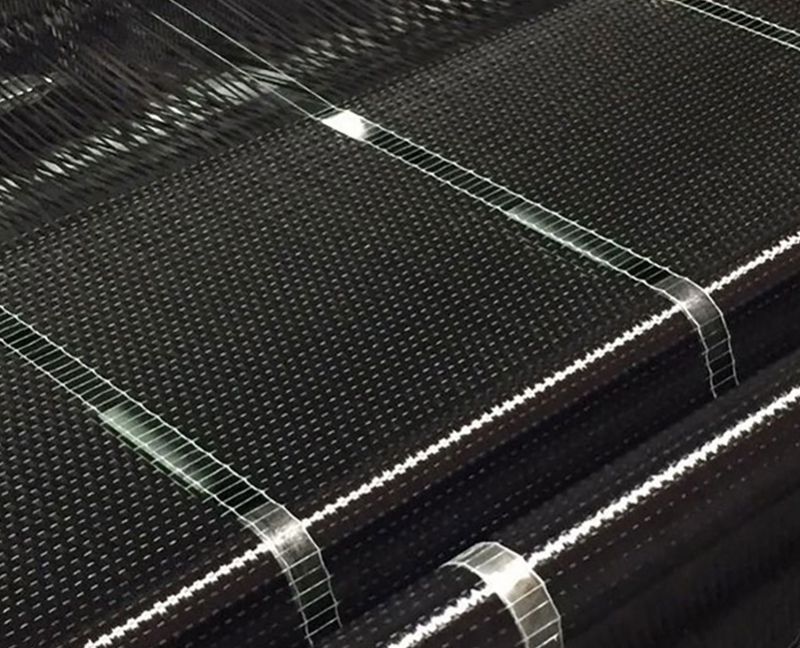

| Product name | Carbon Fiber Cloth 6k 3k Custom | ||

| MOQ | ≥1000 square meters | ||

| Application | •Aircraft main, tail and body; automobile engines, synchronizers, hoods, bumpers, decorative parts, etc.; bicycle frames, wheels, faucets; rackets, silver basins; kayaks, snowboards; various models, helmets, and building reinforcements Reinforcement, watches, pens, luggage.Transportation: cars, buses, tankers, tanks, liquefied gas cylinders. | ||

| Feature | • Small thickness, easy to cross and overlap, can be bent and wound forming, suitable for reinforcement of various curved surfaces and special-shaped components. •Carbon fiber has high tensile strength, acid and alkali resistance, and corrosion resistance. • Non-toxic and non-irritating smell, construction can still be done in residence. •Light weight, the specific gravity is 23% of the steel, basically does not increase the weight of the component, and does not change the section size of the component. | ||

PERFORMANCE ATTRIBUTES

NON-TOXIC AND NON-IRRITATING SMELL

HIGH TENSILE STRENGTH

CORROSION RESISTANCE

Light weight

Carbon fabric specification

| Type | Reinforcement Yarn | Weave | Fiber Count(Wmm) | Weight(g/m2) | Thickness (mm) | Width(cm) | ||

| Warp Yarn | Weft Yam | Warp Ends | Weft Picks | |||||

| SAD-1K-P | 1K | 1K | (Plain) | 9 | 9 | 120 | 0.16 | 100 |

| SAD-1K-X | 1K | 1K | (Twill) | 9 | 9 | 120 | 0.16 | 100 |

| SAD-1K-P | 1K | 1K | (Plain) | 10.5 | 10.5 | 140 | 0.17 | 100 |

| SAD-1K-X | 1K | 1K | (Twill) | 10.5 | 10.5 | 140 | 0.17 | 100 |

| SAD-3K-P | 3K | 3K | (Plain) | 5 | 5 | 200 | 0.3 | 100 |

| SAD-3K-X | 3K | 3K | (Twill) | 5 | 5 | 200 | 0.3 | 100 |

| SAD-3K-P | 3K | 3K | (Plain) | 6 | 6 | 240 | 0.32 | 100 |

| SAD-3K-X | 3K | 3K | (Twill) | 6 | 6 | 240 | 0.32 | 100 |

| SAD-3K-P | 3K | 3K | (Plain) | 7 | 7 | 280 | 0.34 | 100 |

| SAD-3K-X | 3K | 3K | (Twill) | 7 | 7 | 280 | 0.34 | 100 |

| SAD-6K-P | 6K | 6K | (Plain) | 4 | 4 | 320 | 0.38 | 100 |

| SAD-6K-X | 6K | 6K | (Twill) | 4 | 4 | 320 | 0.38 | 100 |

| SAD-6K-P | 6K | 6K | (Plain) | 5 | 5 | 400 | 0.42 | 100 |

| SAD-6K-X | 6K | 6K | (Twill) | 5 | 5 | 400 | 0.42 | 100 |

| SAD-12K-P | 12K | 12K | (Plain) | 2.5 | 2.5 | 400 | 0.46 | 100 |

| SAD-12K-X | 12K | 12K | (Plain) | 3 | 3 | 480 | 0.52 | 100 |

| SAD-12K-P | 12K | 12K | (Twill) | 3 | 3 | 480 | 0.52 | 100 |

| SAD-12K-X | 12K | 12K | (TwiH) | 4 | 4 | 640 | 0.64 | 100 |

Application

•Aircraft main, tail and body; automobile engines, synchronizers, hoods, bumpers, decorative parts, etc.; bicycle frames, wheels, faucets; rackets, silver basins; kayaks, snowboards; various models, helmets, and building reinforcements Reinforcement, watches, pens, luggage. Transportation: cars, buses, tankers, tanks, liquefied gas cylinders.

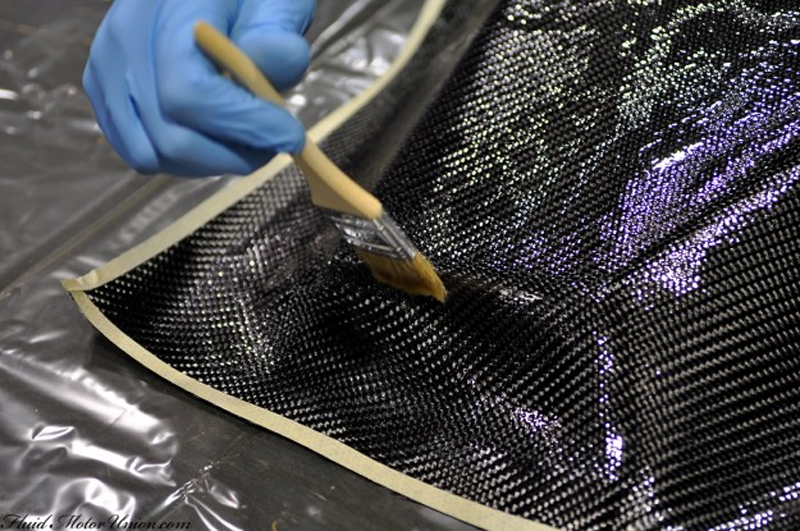

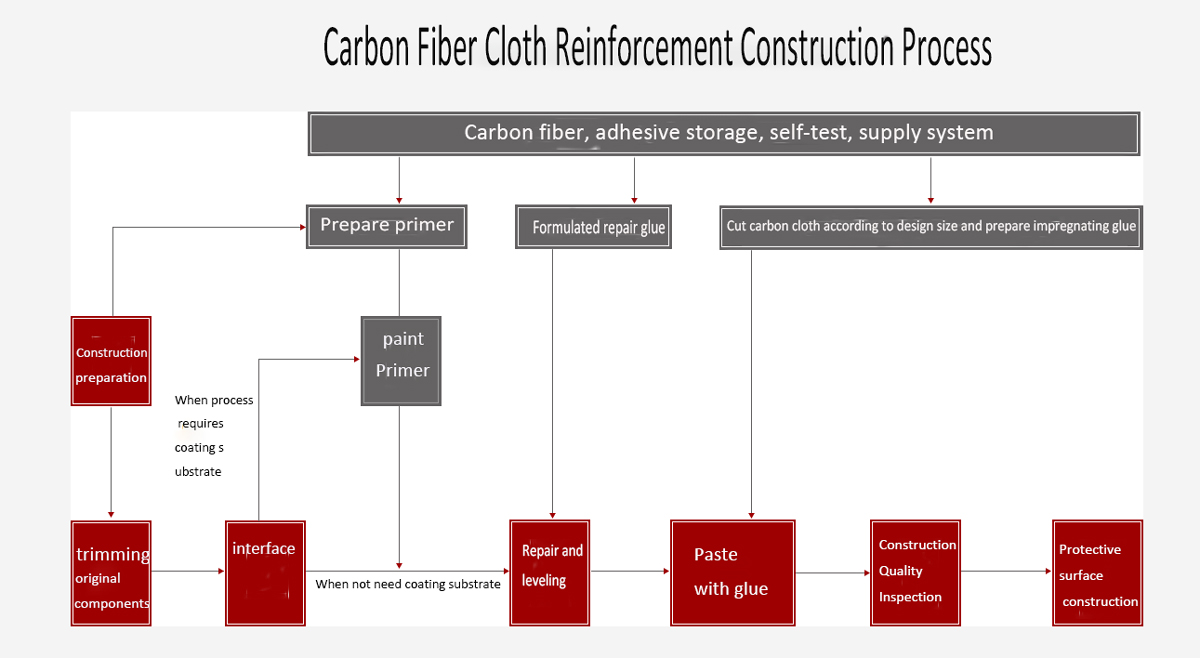

Carbon Fiber cloth Reinforcement Construction Process

SUCCESSFUL CASES

It use for Industry, fire protection, construction, aerospace

Carbon fiber cloth is used for tensile,shear and seismic reinforcement of structural components. This material can be used together with supporting adhesives to form a complete carbon fiber cloth reinforcement system. The system is suitable for beams, columns, slabs, tunnels, circles, arcs, etc. It is widely use for Civil construction, bridge, tunnel, concrete structure anti-seismic, reinforcement, reinforcing material.ZBREHON Carbon Fiber Cloth use to repair steel pipe corrosion on transmission towers..The innovation eliminates the need for special jigs and methods in replacement work by reinforcing pitted and corroded pipes, thus also reducing lead times for strength assessments and cutting construction costs. Another key factor in receiving this award was the broad social benefits that could accrue from applying this technology to steel-framed buildings and other structures.

Carbon fiber cloth is used for tensile,shear and seismic reinforcement of structural components. This material can be used together with supporting adhesives to form a complete carbon fiber cloth reinforcement system. The system is suitable for beams, columns, slabs, tunnels, circles, arcs, etc. It is widely use for Civil construction, bridge, tunnel, concrete structure anti-seismic, reinforcement, reinforcing material.ZBREHON Carbon Fiber Cloth use to repair steel pipe corrosion on transmission towers..The innovation eliminates the need for special jigs and methods in replacement work by reinforcing pitted and corroded pipes, thus also reducing lead times for strength assessments and cutting construction costs. Another key factor in receiving this award was the broad social benefits that could accrue from applying this technology to steel-framed buildings and other structures.